Nā huahana

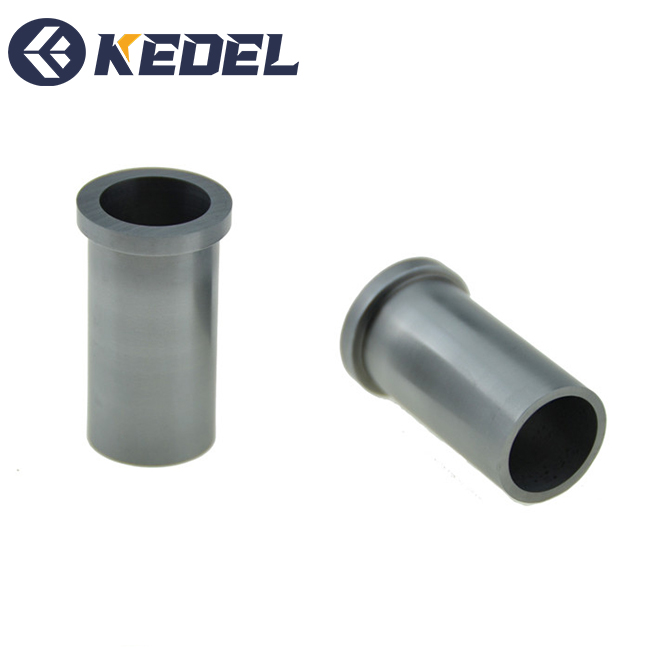

ʻAi ʻAi ʻino Tungsten Carbide Solid YG1C Threaded Drill Bushings

Hoʻolauna Huahana

ʻO ka tungsten carbide bushing i hoʻonohonoho ʻia e nā mea tungsten carbide puʻupaʻa.Hōʻike ia i ka paʻakikī kiʻekiʻe a me ka ikaika kulou.Loaʻa ka hana ʻoi aku ka maikaʻi ma ke kūʻē ʻana i ka abrasion a me ka corrosion, i hoʻohana nui ʻia i nā ʻoihana he nui

No kona hoʻohana nui ʻana.Hoʻohana pinepine ʻia ʻo Tungsten carbide bushing me ka pololei kiʻekiʻe, a ma muli o ko lākou hoʻopau piha ʻana, ka nui kikoʻī, ka lōʻihi a me ke kūpaʻa corrosion.Mahalo nui ʻia kēia mau mea e nā mea kūʻai aku ma ka mākeke domistic a ma luna.

Eia kekahi, ʻokoʻa mai nā ʻano like ʻole o ke kaiapuni noi.Nui nā ʻano o ka tungsten carbide bushing.Hoʻopilikino ʻia ka hapa nui o nā kikoʻī.Ua kākoʻo ʻia ʻo Kedel Tool e ka ʻike ʻoihana waiwai a me ka ʻike hana ʻana o nā ʻano carbide bushing like ʻole.Hiki i kēia ke hana i nā ʻano like ʻole o Tungsten carbide bushing e pili ana i ka hoʻolālā kikoʻī.

Nā hiʻohiʻona huahana

1. E hoʻohana i ka 100% tungsten carbide maka

2. Nā waiwai kemika paʻa

3. ʻO ka hana maikaʻi a me ka ʻaʻahu maikaʻi / pale ʻana i ka corrosion

4. HIP sintering, maikaʻi compactness

5. Blanks, kiʻekiʻe machining pololei / pololei

6. Loaʻa nā ʻano nui o OEM

7. Hāʻawi hale hana

8. Nānā maikaʻi nā huahana koʻikoʻi

Kiʻi kikoʻī

Pākaukau mea

| Papa | ISO | Hōʻike | Ka hoʻohana ʻana i ka tungsten carbide | ||

| ʻO ka mānoanoa | TRS | ʻoʻoleʻa | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | He kūpono no ka hana ʻana i ka hao hoʻoheheʻe ʻia, ka hao hao, ke kila refractory a me ke kila kila.Pono no ka hana ʻana i ka hao hoʻoheheʻe maʻamau. |

| YG06 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | He kūpono no ka mīkini hoʻopau a me ka mīkini semi-finish no ka hao hoʻoheheʻe ʻia, ka metala non-ferrous, ka hao a me nā mea i hoʻohui ʻole ʻia.He kūpono hoʻi no ke kaha kiʻi uea no ke kila a me ka metala non-ferrous, wili uila no ka hoʻohana geology a me ka drill kila etc. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | He kūpono no ka hana ʻino ʻana i ka hao hao, metala non-ferrous, nā mea metala ʻole, ke kaha kiʻi o ke kila, nā metala non-ferrous a me nā paipu, nā ʻano hoʻoheheʻe like ʻole no ka hoʻohana ʻana i ka geology, nā mea hana no ka mīkini hana a me nā ʻāpana. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | He kūpono no ka mīkini ʻokiʻoki haʻahaʻa, wili i ka titanium alloy a me ka refractory alloy, ʻoi aku hoʻi no ka mea hana ʻoki ʻoki a me ke kui siliki. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Kuʻi no ka hoʻoheheʻe ʻana i nā mea hoʻoheheʻe no ka wili pōhaku kaumaha: nā ʻāpana hiki ke hoʻohana ʻia no ka wili lua hohonu, trolley drill pōhaku etc. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Kūpono no ka ʻeli pōhaku paʻakikī, nā kī kila me nā lakio hoʻoemi kiʻekiʻe, kiʻi paipu, nā mea hana punching, ke keʻena kumu o ka pauka metallurgy molders automatic molders etc. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Kūpono no ka hana ʻana i nā mea make me ka hopena haʻahaʻa e like me ke kuʻi ʻana i nā ʻāpana wati, nā pūpū pākaukau, nā pāpale liʻiliʻi liʻiliʻi etc. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Kūpono no ka hana ʻana i ke poʻomanaʻo o ke poʻo anu, ke kuʻi anu a me ke kaomi anu i hoʻohana ʻia no ka hana ʻana i nā ʻāpana maʻamau, bearings etc. | |