Nā huahana

ʻO ka pale ʻana i ka corrosion polished Tungsten Carbide Bushing Sleeve

Hoʻolauna Huahana

E hoʻohana nui ʻia ka lima axle carbide cemented no ke kākoʻo ʻana i ke kākoʻo, hoʻohālikelike i ka anti-thrust a me ke sila o ke axle o ka moter, centrifuge, pale a me ka mea hoʻokaʻawale o ka pauma uila i loko o nā kūlana hana ʻino o ke kiʻekiʻe kiʻekiʻe o ka hoʻololi ʻana, ke one lash abrasion a me ke kinoea corrossion i loko o ka māla aila, e like me ka paheʻe lima lima, ka lima lima lima lima, ka lima lima lima, ka lima lima lima, ka lima lima lima, ka lima lima lima, ka lima lima lima lima, ka lima lima lima, ka lima lima a me ka lima lima. lima lima.

Nā pono

1. 100% puʻupaʻa maka mea.

2. Loaʻa nā ʻano helu like ʻole ma muli o ke noi a ka mea kūʻai aku.

3. loaʻa iā mākou ka laina hana kiʻekiʻe ʻoihana a me nā lako inspeciton e hōʻoia i nā huahana kiʻekiʻe.

4. ʻO ka Ground pololei a me ke kaʻina polishing kiʻekiʻe

5. Kiʻekiʻe ʻaʻahu kūpaʻa, kiʻekiʻe paʻakikī a me ka paʻakikī hopena

6. ʻenehana holomua, wili pololei.

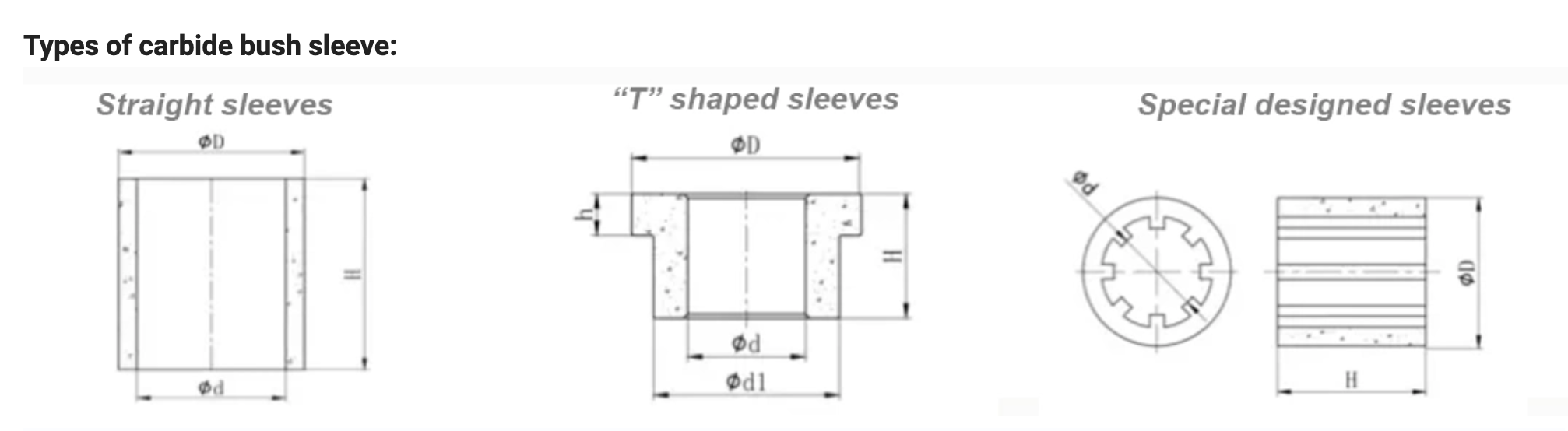

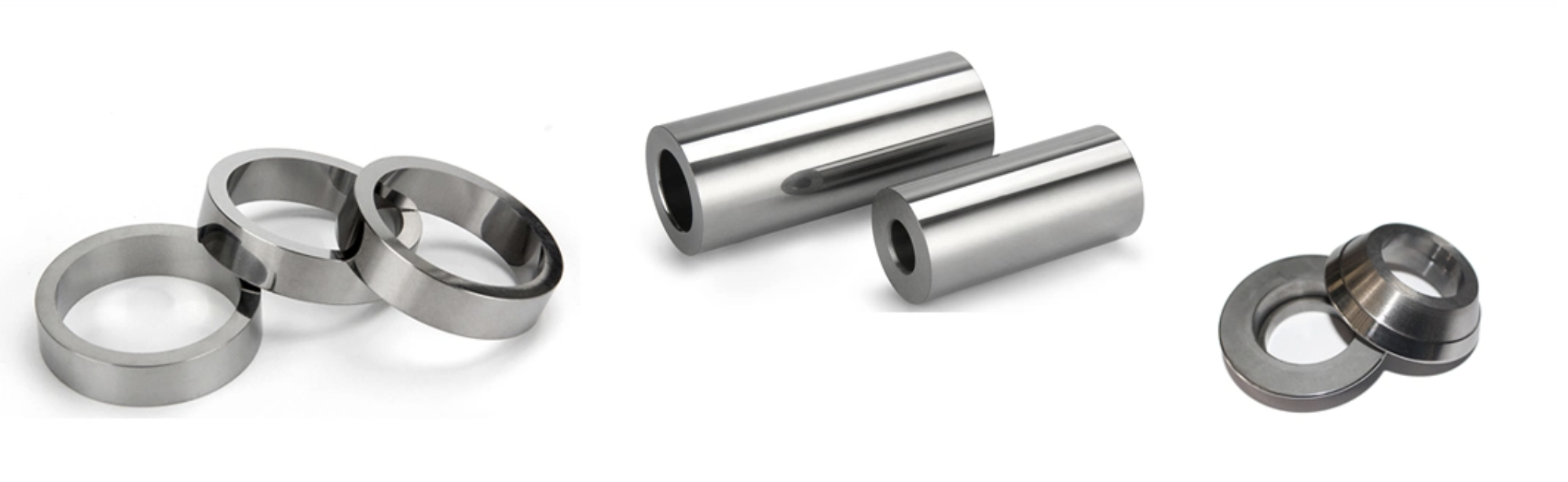

ʻAno pahu

Kiʻi pahu

Pākaukau mea

| Papa | ISO | Hōʻike | Ka hoʻohana ʻana i ka tungsten carbide | ||

| ʻO ka mānoanoa | TRS | ʻoʻoleʻa | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | He kūpono no ka hana ʻana i ka hao hoʻoheheʻe ʻia, ka hao hao, ke kila refractory a me ke kila kila. Pono no ka hana ʻana i ka hao hoʻoheheʻe maʻamau. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | He kūpono no ka mīkini hoʻopau a me ka mīkini semi-finish no ka hao hoʻoheheʻe ʻia, ka metala non-ferrous, ka hao a me nā mea i hoʻohui ʻole ʻia. He kūpono hoʻi no ke kaha kiʻi uea no ke kila a me ka metala non-ferrous, wili uila no ka hoʻohana geology a me ka drill kila etc. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | He kūpono no ka hana ʻino ʻana i ka hao hao, metala non-ferrous, nā mea metala ʻole, ke kaha kiʻi o ke kila, nā metala non-ferrous a me nā paipu, nā ʻano hoʻoheheʻe like ʻole no ka hoʻohana ʻana i ka geology, nā mea hana no ka mīkini hana a me nā ʻāpana. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | He kūpono no ka mīkini ʻokiʻoki haʻahaʻa, wili i ka titanium alloy a me ka refractory alloy, ʻoi aku hoʻi no ka mea hana ʻoki ʻoki a me ke kui siliki. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Kuʻi no ka hoʻoheheʻe ʻana i nā mea hoʻoheheʻe no ka wili pōhaku kaumaha: nā ʻāpana hiki ke hoʻohana ʻia no ka wili lua hohonu, trolley drill pōhaku etc. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Kūpono no ka ʻeli pōhaku paʻakikī, nā kī kila me nā lakio hoʻoemi kiʻekiʻe, kiʻi paipu, nā mea hana punching, ke keʻena kumu o ka pauka metallurgy molders automatic molders etc. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Kūpono no ka hana ʻana i nā mea make me ka hopena haʻahaʻa e like me ke kuʻi ʻana i nā ʻāpana wati, nā pūpū pākaukau, nā pāpale liʻiliʻi liʻiliʻi etc. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Kūpono no ka hana ʻana i ke poʻomanaʻo o ke poʻo anu, ke kuʻi anu a me ke kaomi anu i hoʻohana ʻia no ka hana ʻana i nā ʻāpana maʻamau, bearings etc. | |