Nā huahana

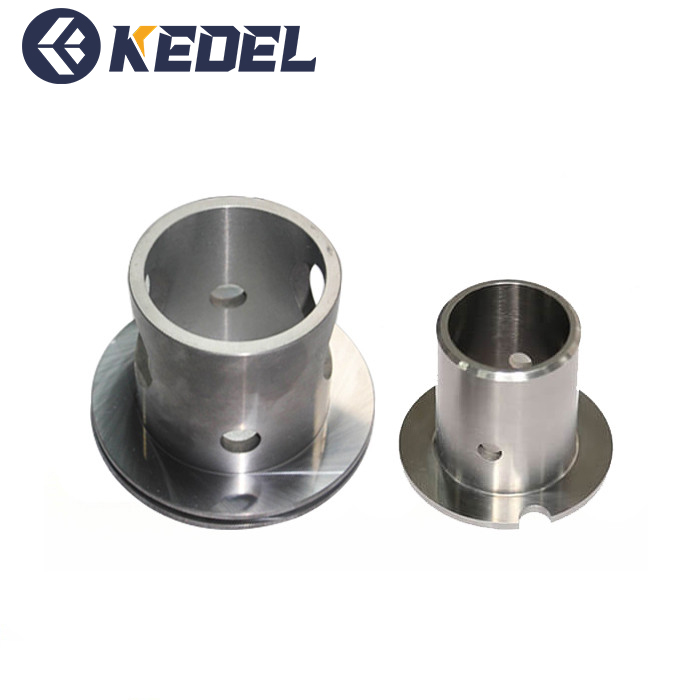

Hoʻopilikino ʻia ʻo Tungsten carbide Bushing Shaft Sleeve

Hoʻolauna Huahana

He ākea ka noi ʻana o ka tungsten carbide bush, kahi mea e pale ai i kahi papa o nā ʻāpana. Aia i loko o ka hana maoli a me ke kuleana a me ke kumu o kāna kaiapuni noi he pilina nui. ʻO nā noi valve, e hoʻokomo ʻia nā bushings i loko o ka pahele pahu pahu pahu, i mea e hōʻemi ai i ka leakage valve, e sila ai; nā noi e halihali ana, ka hoʻohana ʻana i ka lāʻau e hōʻemi i ka ʻaʻahu ma waena o ka bearing a me ka noho kumu, e pale i ke āpau ma waena o ke kumu a me ka piʻi ʻana o ka lua a pēlā aku. ʻO Tungsten carbide bush production a me ka hana ʻana o ka ikaika kiʻekiʻe, hiki ke kū i ka ukana lōʻihi, me ke kūpaʻa kemika kiʻekiʻe, alkali, waiʻona, ether, hydrocarbons, acid, aila, detergent, wai (wai kai), a ʻaʻohe ʻala , non-toxic, tasteless, non-rust hiʻohiʻona, ua hoʻohana nui ʻia i ka ʻoihana petrochemical no Submerged Oil Pump, slurry pump, slurry pump.

Nā hiʻohiʻona huahana

1. Loaʻa i ka Tungsten Carbide Bearing Bushings nā hiʻohiʻona o ke kūpaʻa ʻaʻahu kiʻekiʻe, ke kūpaʻa corrosion kiʻekiʻe a me nā waiwai compressive maikaʻi.

2. Hoʻohana nui ʻia ia i nā ʻoihana petrochemical a me nā ʻoihana ʻē aʻe e kāhea ana i nā waiwai kiʻekiʻe o ka bearing bushings a i ʻole nā lima lima.

3. ʻO Tungsten carbide BEARING ka mea maʻamau i waena o nā mea frictional. Hoʻohana nui ʻia lākou e like me nā ʻāpana kumu no ka hoʻopaʻa ʻana. A hoʻohana nui ʻia nā bushings i ka ʻoihana petrochemical ma muli o kāna mau hana maikaʻi loa e like me ke kapa komo, anti corrosion etc.

Kaʻina Hana Hana

Milling--Hoʻohālikelike e like me ka mea e koi ʻia ai--Wīwī Wet--Dry--Granulation--Press--Sinter--Inspection--Package

Nā huahana pili

ʻO nā mea hoʻoheheʻe Tungsten Carbide

Nā lima Carbide no ka pauma centrifugal

Alakaʻi Drill Tungsten

ʻO nā lima ʻākiʻi Carbide

Pākuʻi Carbide

Na Poepoe Pahu Carbide.

Nā Noho a me nā Puka Tungsten Carbide Valve

ʻO ka ʻaila Tungsten Carbide a me nā ʻāpana a me nā ʻāpana

Nā Nozzles Tungsten Carbide

ʻO nā ʻāpana ʻo Tungsten Carbide High Pressure Pump

ʻO Tungsten Carbide no nā mea hoʻopaʻa kahe

Nā ʻĀpana Pum Centrifugal

ʻAʻahu ʻulaʻula ʻeleʻele Centrifugal Carbide

Ka nui o ka huahana

Pākaukau mea

| Papa | ISO | Hōʻike | Ka hoʻohana ʻana i ka tungsten carbide | ||

| ʻO ka mānoanoa | TRS | ʻoʻoleʻa | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | He kūpono no ka hana ʻana i ka hao hoʻoheheʻe ʻia, ka hao hao, ke kila refractory a me ke kila kila. Pono no ka hana ʻana i ka hao hoʻoheheʻe maʻamau. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | He kūpono no ka mīkini hoʻopau a me ka mīkini semi-finish no ka hao hoʻoheheʻe ʻia, ka metala non-ferrous, ka hao a me nā mea i hoʻohui ʻole ʻia. He kūpono hoʻi no ke kaha kiʻi uea no ke kila a me ka metala non-ferrous, wili uila no ka hoʻohana geology a me ka drill kila etc. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | He kūpono no ka hana ʻino ʻana i ka hao hao, metala non-ferrous, nā mea metala ʻole, ke kaha kiʻi o ke kila, nā metala non-ferrous a me nā paipu, nā ʻano hoʻoheheʻe like ʻole no ka hoʻohana ʻana i ka geology, nā mea hana no ka mīkini hana a me nā ʻāpana. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | He kūpono no ka mīkini ʻokiʻoki haʻahaʻa, wili i ka titanium alloy a me ka refractory alloy, ʻoi aku hoʻi no ka mea hana ʻoki ʻoki a me ke kui siliki. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Kuʻi no ka hoʻoheheʻe ʻana i nā mea hoʻoheheʻe no ka wili pōhaku kaumaha: nā ʻāpana hiki ke hoʻohana ʻia no ka wili lua hohonu, trolley drill pōhaku etc. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Kūpono no ka ʻeli pōhaku paʻakikī, nā kī kila me nā lakio hoʻoemi kiʻekiʻe, kiʻi paipu, nā mea hana punching, ke keʻena kumu o ka pauka metallurgy molders automatic molders etc. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Kūpono no ka hana ʻana i nā mea make me ka hopena haʻahaʻa e like me ke kuʻi ʻana i nā ʻāpana wati, nā pūpū pākaukau, nā pāpale liʻiliʻi liʻiliʻi etc. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Kūpono no ka hana ʻana i ke poʻomanaʻo o ke poʻo anu, ke kuʻi anu a me ke kaomi anu i hoʻohana ʻia no ka hana ʻana i nā ʻāpana maʻamau, bearings etc. | |